In the context of the dual carbon goals, we have come to the critical period of PV cell technology iteration. As the traditional PERC mono-crystalline cell has nearly reached its efficiency limit, HJT and TOPcon cells are competing to become the next mainstream technical route. To date, the maximum laboratory efficiency of HJT is 26.81%, which is far superior to that of TOPCon, so its prospects are quite optimistic.

To solve the problems of heterojunction cells such as their large consumption of silver paste, weak adhesive strength and moisture sensitivity, Crown developed an encapsulation busbar carrier film, heterojunction cell skin film, exclusive heterojunction cell POE film and highly water-resistant backsheet that are suitable for HJT cells, thus going further with reducing cost and improving efficiency through the encapsulating material.

Boom of N-type technology, immense potential of HJT technology

In terms of performance, HJT cells possess the advantages of both crystalline silicon cells and thin-film solar cells, and are characterized by high conversion efficiency, low light-induced degradation, high stability and low degradation rate. HJT technology has immense potential and is expected to become one of the mainstream cell technologies in the future. As of today, equipment is no longer the core factor constraining HJT technology. In the short and medium term, enterprises will be more concerned with lamellar wafer formation, silver paste consumption reduction (non-silicon cost) and target material price reduction.

Busbar-free + encapsulation busbar carrier film, silver paste consumption reduced by 45%

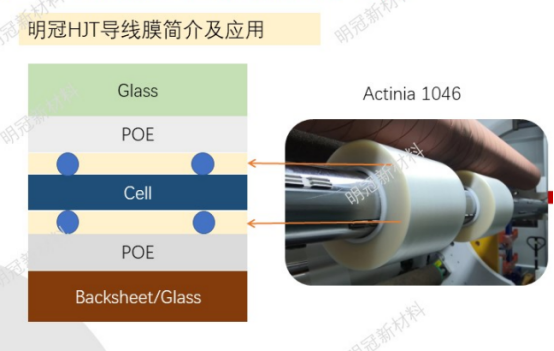

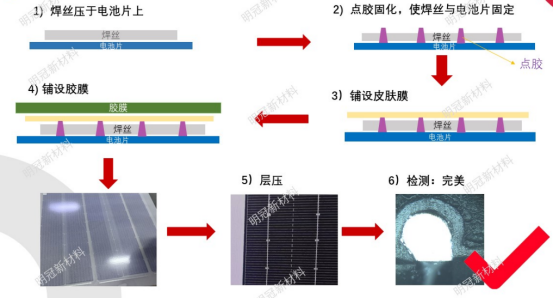

To reduce silver paste consumption, Crown invented busbar-free cell technology. Thanks to the surface conductivity of HJT cells, the metallic busbar electrode was removed and a low-temperature alloy coated copper wire directly fitted around the TCO, reducing the cell area blocked by the ribbon and soldering point, and creating ohmic contact. This is how busbar-free cells were created. This new technology imposed new requirements for cell encapsulation. Therefore, Crown developed the heterojunction cell encapsulation busbar carrier film Actinia1046. The combination of conductive wire and carrier film with the string connection, stacking and lamination methods allow the low-temperature soldering wire and cell to be fully fitted, strengthen the adhesion between wire and cell, and reduce the low-temperature silver paste consumption of HJT cells by 45% to 100 mg, thereby substantially reducing their cost. In addition, heterojunction cell encapsulation busbar carrier film Actinia1046 has excellent light transmittance and processability. It allows full contact between the low-temperature soldering wire and cell without blocking the light or heat, creates a good circuit inside the module and enhances the product yield and photoelectric conversion efficiency.

MBB technology + cell skin film, enhanced module reliability

For the MBB technology that has a greater presence in the market, Crown has developed a cell skin film. Unlike traditional encapsulation in which the soldering wire is directly bonded with the encapsulation film, the cell skin film can be placed between the soldering wire and encapsulation film, effectively preventing the desoldering of the cell. After PCT96h and CH2000 tests, HJT cells still have good stripping resistance, good UV resistance, excellent adhesive strength and low fluidity, effectively maintaining adequate contact between busbar and cell, preventing migration and effectively reducing electrical resistance and power degradation. This film is also of the same type as other encapsulating materials such as POE/EVA in that it has excellent adhesive strength, is able to prevent bubbling, fragmentation, cell-cell adhesion and migration, and improves module reliability. This film is visually concealed to meet the aesthetic requirements of the module.

Exclusive heterojunction cell POE film passes verification by customers and enters large-scale use

At present, the poor suitability of HJT cell encapsulation technology is a big problem for cell manufacturers. With this new opportunity, Crown is the first manufacturer to develop an exclusive heterojunction cell POE film. Due to the structural differences between POE and EVA, the water permeability of POE is only 2.6 g/m2 per day, which is far less than that of EVA, meeting the high water resistance requirements of HJT cells. After DH3000 testing, the appearance of POE film shows no noticeable change, and its adhesive strength is greatly superior to that of common POE film. This product has passed PID192h testing by customers and is used on a large scale.

Highly water-resistant backsheets with excellent market performance, expected to prevail in the market soon

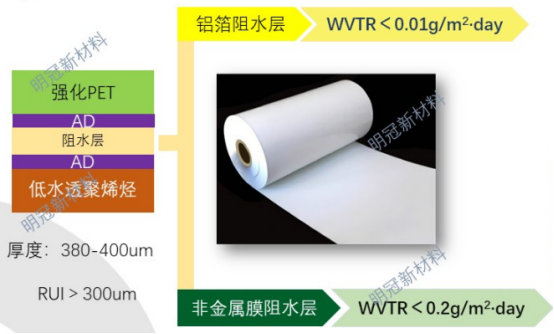

HJT cells are subject to high water permeability requirements, and the water permeability of the common backsheets on the market is about 1.8–2.3 g/m2 per day (infrared method: 38°C, 90%RH). The highly water-resistant backsheets developed by Crown are produced by combining the water insulation layer, reinforced PET and low-permeability polyolefin. The water insulation layer is made of aluminum foil with a water permeability reduced to below 0.01 g/m2 per day. If the water insulation layer is made of non-metallic film, its water permeability can be reduced to below 0.2 g/m2 per day, which is considerably superior to that of common backsheets. The highly water-resistant backsheets also have superstrong UV resistance. After the UV600KWh ageing test, their yellowing coefficient is only 2.3, meeting the 25-year service life requirement for the Class 1 region of the country. Furthermore, the highly water-resistant backsheets have strong hydrolysis resistance. After the PCT48h test, they show no delamination during pulling and stripping. After the water boiling ageing test, they still have strong stripping resistance. Now, many HJT solar cell module manufacturers are conducting ageing reliability tests on non-metallic highly water-resistant backsheets. It is expected to be marketed soon after testing is complete.

The cost reduction and efficiency improvement of heterojunction cells are not just achieved through "higher efficiency", "lamellar form", "desilverization" and "indium removal", but also through the encapsulation method. Crown is once again the first manufacturer to develop various encapsulation products suitable for HJT cells, such as encapsulation busbar carrier film, heterojunction cell skin film, exclusive heterojunction cell POE film and highly water-resistant backsheets. Crown provides high-quality encapsulation solutions, opens new paths for the cost reduction and efficiency improvement of cells, and optimizes the quality and efficiency of high-efficiency modules.

Home

Home